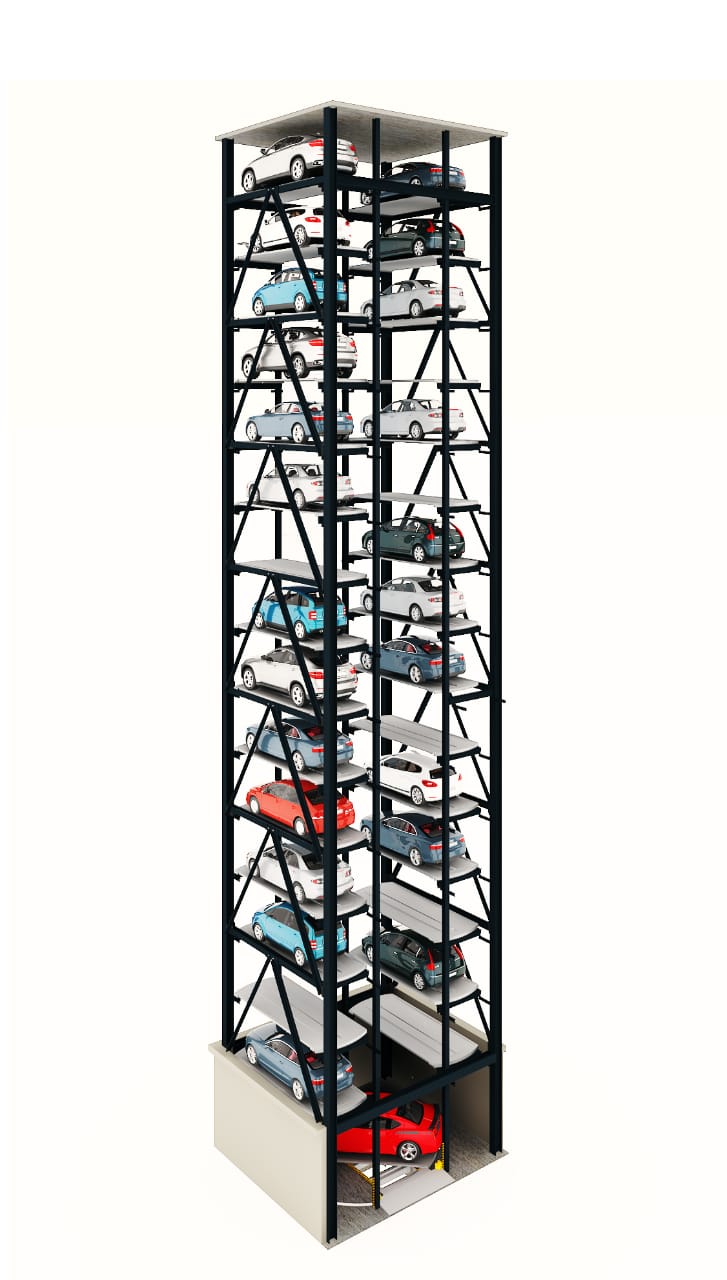

CANTON TOWER CAR PARKING SYSTEM is very fast & cost-effective system. This has an elevator in the centre & on either side, there are parking spaces. The tower can be built to park up to 60 cars in a place, which can be normally used to park 3 cars only. The car has be parked at the ground level on the elevator. The elevator has the mechanism to shift the car on to either side as well as move vertically up & down. This picks up an unoccupied pallet & brings it to the ground level. After placing the car on it, the parking button had to be pressed which enables the elevator to park the car to a vacant location. To retrieve back the car, de-park button has be pressed which will bring the car to the ground level in the specified time. The system has be covered from the top & on the ground level to ensure the safety of the equipment.

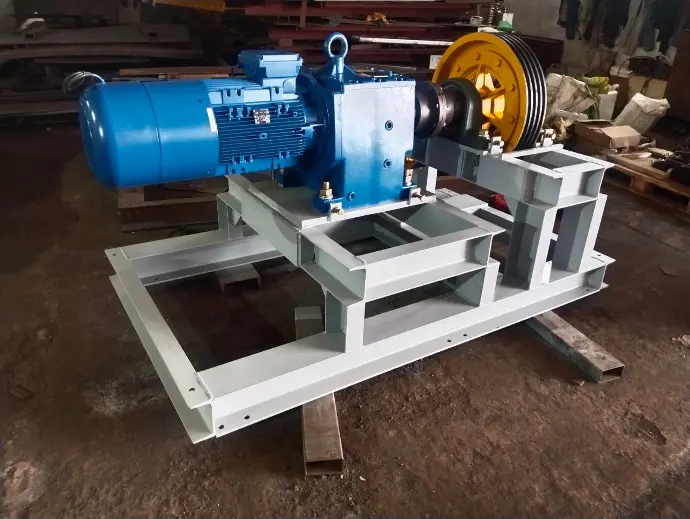

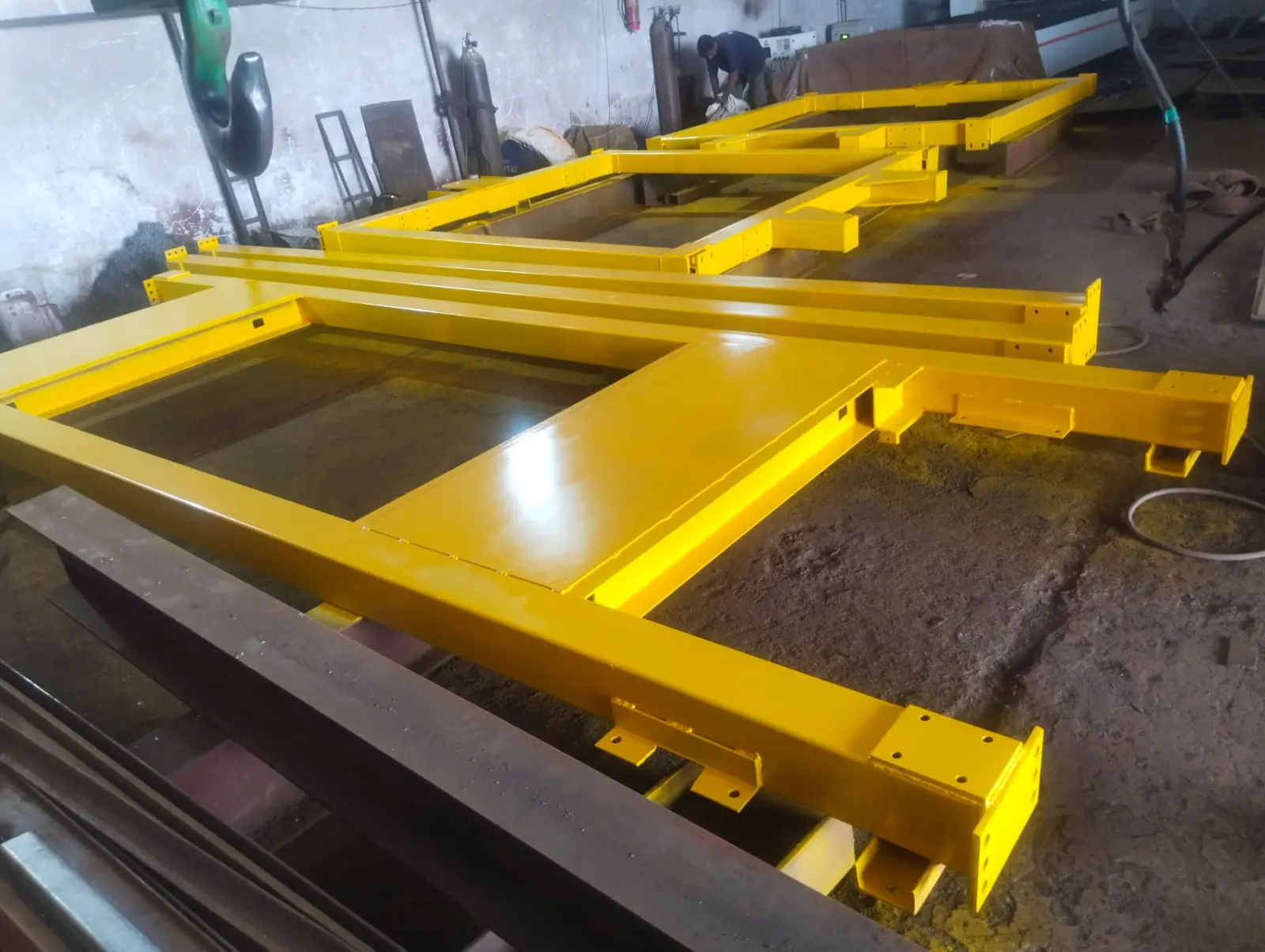

All the pallet shifting mechanisms are mounted on the lift platform. At each side of the platform there are 2 geared motors with one friction wheel, each turning in opposite direction. Each pallet has 6 wheels and a bar in the middle, where the friction wheels act. The two friction wheel groups are mounted on a knock-out system driven by a central geared motor over a rack & pinion system, which can slide out on each side of the platform. The pallets have no mechanism, they need just 3 steel beams on which they can slide and 2 idle rolls to guide them.

Advantages at a glance

Excellent solution where ground parking space is scarce, expensive and congested.

Modular design adaptable to most scenarios

Very efficient retrieval time is accomplished in less than two to three minutes.

A rotating platform parks and retrieves cars facing in the driving direction

Combination of lift, Storage and retrieval unit (SRU), and Turntable for optimum performance

Can be customized for specific car types

Various Permutations/Combinations possible by placing systems adjacent or behind each other

Intelligent allocation of vehicles within the system for shorter access times

Several parking spaces per system possible

Simple operating procedures for users, even at peak times and when traffic is heavy

Excellent protection against pilferage and damage small footprint

Highlights

- The system can be for 2 Ton or 2.5 Ton car handling capacity. Higher loads per parking space possible on request

- Auto door sensor activated Entry and Exits can be at different levels

- An optional turntable mechanism can rotate the car 180 Deg

- The system is designed to handle SUV, MUV, Hatchback, Sedan cars

- Fully automated PLC intelligent control system and perfect security, there's light guide when cars in/out the garage, car over length monitor , speed limit protection and multiple mechanical interlock; all guarantee the safety of car and personnel.

- No need for complicated ventilation system or expensive lighting

System Features

The Tower system is a fully-automated vertical solution used to multiply parking capacity by utilizing vertical space where ground space is limited.

The systems consist of Car lift, SRU, Turntable, Integrated computer system.

The lift elevates or descends the pallets in the vertical plane, and the transfer mechanism moves it horizontally left or right into parking slots selected by intelligent Automation

Multiple layers of network sensors and limit switches prevents any contact between vehicle bodies and the walls of the structure. Cars have maximum protection.

The overall operation can be viewed with one screen and has an excellent human machine interface for ease of operation.

This system is suitable for medium or large-scale buildings. It can also be used as a stand-alone tower for pay and park business in private and municipalities. Since it is controlled by an integrated computer system, the overall operation can be viewed with one screen and its operation is very user-friendly. We incorporate German/Italian motors, Mitusubishi or equivalent drives and PLC’s.

Models

ST – Open Standalone Steel Structure Tower

RCT – Closed RCC Tower with Vertical Steel Columns within the RCC shaft

RBT – Closed RCC Tower with brackets fixed onto the RCC shaft